Process Capability (Cp & Cpk)

Process Capability

This is a story of Cpk and Ppk, before start reading please check blog six sigma on the lin: https://freeknowle.blogspot.com/2020/09/six-sigma.html

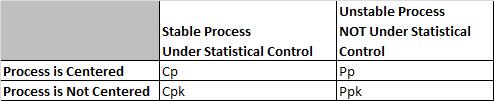

What is the Difference between Cp, Cpk and Pp,

PPk?

Cp Cpk vs Pp Ppk

Cp and Cpk are called Process Capability. Pp

and Ppk are called Process Performance. In both cases we want to try to verify

if the process can meet to meet Customer

CTQs (requirements).

Cp, and Cpk are used for Process Capability.

Generally you use this when a process is under statistical control.

This often happens with a mature process that has been around for a while.

Process capability uses the process sigma value determined from either the

Moving Range, Range or Sigma control charts

Pp and PPk are used for Process Performance.

Generally you use this when a process is too new to

determine if it is under statistical control. Ex. there is a short

pre-production run or you are piloting a new process. Because there is not a lot of historical data we take large samples from the process to account for variation. Process Performance generally uses sample sigma in its

calculation.

In theory Cpk will always be greater than or

equal to Ppk. There are anomalies seen when the sample size is small and the

data represents a short amount of time where estimating using R will overstate

standard deviation and make Cpk smaller than Ppk. It is not real, there can

never be less variation in the long term since the long term is using all of

the data not just two pieces of data from every subgroup.

Evaluating process capability with Cp &

Cpk mirror what is done (and why it is done) when following the Pp & Ppk approach. The main difference is that you use Cp &

Cpk after a process has reached stability or statistical control.

Cpk vs Ppk

Ppk tells us how a

process has performed in the past and you cannot use it predict the future

because the process is not in a state of control.

If a process is in statistical control;

The values for Cpk and Ppk will converge to almost the same value because sigma and the sample standard deviation will be identical (use an F test to determine).

In other words, if Cpk == Ppk, the process is

likely in statistical control.

If a process is NOT in statistical control;

Cpk and Ppk values will be distinctly

different, perhaps by a very wide margin.

What is the Difference Between Cp and Cpk?

Cp vs Cpk

Cp and Cpk measure how consistent you are to

around your average performance.

The ‘k’ stands for ‘centralizing factor.’ The

index takes into consideration the fact that your data is maybe not centered.

Cpk tells us what a

process is capable of doing in future, assuming it remains in a state of

statistical control.

The Shooting at a Target Analogy

In a perfectly centered data set, there will

be no difference between Cp and Cpk. Think of throwing darts at a dart board

and having the center of the bull’s eye be the 0,0 on a cartesian plane and the

edges being out 3 units from that center point (we will use the edge of the

dart board or 3 and -3 as our USL and LSL). In a perfectly centered sample of

darts, your average distance from the center, or Mu, will be 0. A little

algebra will show us that that your Cpk and Cp numbers come out the same.

Min((0- -3)/3s , (3-0)/3s) = (3- -3)/6s = 1s .

Things get a little harrier when the darts

move up, say to be centered at an average of 2 units above center. Now you end

up with a Cpk of (3-2)/3s = 1/3s, but your Cp is still the same 1s as before.

It is important to note that because Cpk uses the minimum function, it will

always be equal to or smaller than the Cp for the same set of data.

What is Cpk?

The Parking a Car in the Garage Analogy

If you think of the walls of your garage –

where you have to fit your car in – they become the customer specification

limits. If you go past those limits, you will crash, and the customer will not

be happy!

If your process has a lot of variation, that

means the process average is all over the place. Not good for parking a car,

and not good for any other process. To give your parking process the best

chance of success you should work on reducing variation and centering.

If the car is too wide for the garage, nothing

you do to center the process will help. You have to change the dispersion of

the process (make the car smaller.)

If the car is a lot smaller than the garage,

it doesn’t matter if you park it exactly in the middle; it will fit and you

have plenty of room on either side. That’s one of the reasons the six sigma

philosophy focuses on removing variation in a process.

If you have a process that is in control and

with little variation, you should be able to park the car easily within the

garage and thus meet customer requirements. Cpk tells you the relationship between the size of the car,

the size of the garage and how far away from the middle of the garage you

parked the car.”

How to Calculate Cpk

Cpk is a measure to show how many standard

deviations the specification limits are from the center of the process. On some

processes you can do this visually. Others require an equation.

To find Cpk you need to calculate a Z score for the upper specification limit (called Z USL) and a Z

score for the lower specification limit (called Z LSL).

Since we are trying to measure how many

standard deviations fit between the center line and the specification limit you should not be surprised that the

value of those limits, the process mean, and the standard deviation are all components of the Z calculation.

Cp is an abbreviation. There are really two

parts; the upper and the lower denoted Cpu and Cpl respectively. Their

equations are:

Cpl = (Process Mean

– LSL)/(3*Standard Deviation)

Cpu = (USL – Process Mean)/(3*Standard

Deviation)

Cpk is merely the smallest value of the Cpl or

Cpu denoted: Cpk= Min (Cpl, Cpu)

Why are we dividing by 3 to find Cpk?

We know that any specification limit has an

upper bound and a lower bound. Because you know that 6 sigmas – or 6 standard

deviations account for nearly all eventualities on a process (assuming normal distribution) you shouldn’t be surprised to see the “/ 3”

because we are looking at only one side of the distribution.

Calculating Cpk using a Z Value

If you have a Z value, the equation is very easy;

Cpk can be determined by dividing the Z score

by three.

A z score is the same as a standard score; the

number of standard deviations above the mean.

Z = x – mean of the population / standard deviation.

Notes and Characteristics of Cpk

Cpk and Centered Processes

If a process is perfectly centered, it has a

Cp of 1. That would indicate that mean was 3 standard deviations away from the upper limit and the lower

limit.

A perfectly centered process – a process who

has a mean exactly in between the 2 specification limits (meaning halfway

between the two will have a Cpk of 1. How is this possible? Let’s check the

math.

If a process is perfectly centered, then we

know that the (USL – Process mean) equals the same thing as the (Process Mean –

LSL). Let’s call that A.

Z USL = USL – Process Mean / Standard

Deviation. then becomes Z USL = A/ Standard Deviation

Z LSL = Process Mean – LSL / Standard

Deviation then becomes Z LSL = A / Standard Deviation.

Comments

Post a Comment