FAILURE MODE AND EFFECTS ANALYSIS (FMEA)

Failure mode effects analysis (FMEA)

Also called: potential failure modes and effects analysis;

failure modes, effects and criticality analysis (FMECA)

Begun in the 1940s by the U.S. military, failure modes and

effects analysis (FMEA) is a step-by-step approach for identifying all possible

failures in a design, a manufacturing or assembly process, or a product or

service. It is a common process analysis

tool.

·

"Failure

modes" means the ways, or modes, in which something might fail.

Failures are any errors or defects, especially ones that affect the customer,

and can be potential or actual.

·

"Effects

analysis" refers to studying the consequences of those failures.

Failures are prioritized according to how serious their

consequences are, how frequently they occur, and how easily they can be

detected. The purpose of the FMEA is to take actions to eliminate or reduce

failures, starting with the highest-priority ones.

Failure modes and effects analysis also documents current

knowledge and actions about the risks of failures, for use in continuous

improvement. FMEA is used during design to prevent failures. Later it’s used

for control, before and during ongoing operation of the process. Ideally, FMEA

begins during the earliest conceptual stages of design and continues throughout

the life of the product or service.

Failure Modes and Effects Analysis Example

WHEN TO USE

FMEA

·

When a process, product, or service is being designed or

redesigned, after quality function

deployment (QFD)

·

When an existing process, product, or service is being applied

in a new way

·

Before developing control plans for a new or modified process

·

When improvement goals are planned for an existing process,

product, or service

·

When analyzing failures of an existing process, product, or

service

·

Periodically throughout the life of the process, product, or

service

FMEA

PROCEDURE

Note: This

is a general procedure. Specific details may vary with standards of your

organization or industry. Before undertaking an FMEA process, learn more about

standards and specific methods in your organization and industry through other

references and training.

1. Assemble

a cross-functional team of

people with diverse knowledge about the process, product or service, and

customer needs. Functions often included are: design, manufacturing, quality,

testing, reliability, maintenance, purchasing (and suppliers), sales, marketing

(and customers), and customer service.

2. Identify

the scope of the FMEA. Is it for concept, system, design, process, or service?

What are the boundaries? How detailed should we be? Use flowcharts to identify the scope and to

make sure every team member understands it in detail.

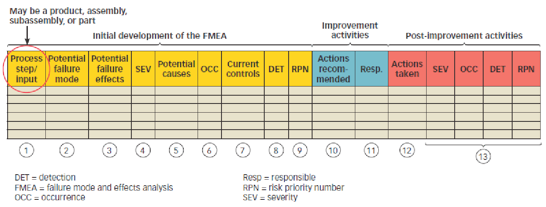

3. Fill

in the identifying information at the top of your FMEA form. (Figure 1 shows a

typical format.) The remaining steps ask for information that will go into the

columns of the form.

Figure

1: FMEA Example

4. Identify

the functions of your scope. Ask, "What is the purpose of this system,

design, process, or service? What do our customers expect it to do?" Name

it with a verb followed by a noun. Usually one will break the scope into

separate subsystems, items, parts, assemblies, or process steps and identify

the function of each.

5. For

each function, identify all the ways failure could happen. These are potential

failure modes. If necessary, go back and rewrite the function with more detail

to be sure the failure modes show a loss of that function.

6. For

each failure mode, identify all the consequences on the system, related

systems, process, related processes, product, service, customer, or

regulations. These are potential effects of failure. Ask, "What does the

customer experience because of this failure? What happens when this failure

occurs?"

7. Determine

how serious each effect is. This is the severity rating, or S. Severity is

usually rated on a scale from 1 to 10, where 1 is insignificant and 10 is

catastrophic. If a failure mode has more than one effect, write on the FMEA

table only the highest severity rating for that failure mode.

8. For

each failure mode, determine all the potential root causes. Use tools

classified as cause analysis tools, as well as the best

knowledge and experience of the team. List all possible causes for each failure

mode on the FMEA form.

9. For

each cause, determine the occurrence rating, or O. This rating estimates the

probability of failure occurring for that reason during the lifetime of your

scope. Occurrence is usually rated on a scale from 1 to 10, where 1 is

extremely unlikely and 10 is inevitable. On the FMEA table, list the occurrence

rating for each cause.

10. For

each cause, identify current process controls. These are tests, procedures or

mechanisms that you now have in place to keep failures from reaching the

customer. These controls might prevent the cause from happening, reduce the

likelihood that it will happen or detect failure after the cause has already

happened but before the customer is affected.

11. For

each control, determine the detection rating, or D. This rating estimates how

well the controls can detect either the cause or its failure mode after they

have happened but before the customer is affected. Detection is usually rated

on a scale from 1 to 10, where 1 means the control is absolutely certain to

detect the problem and 10 means the control is certain not to detect the

problem (or no control exists). On the FMEA table, list the detection rating

for each cause.

12. Optional for most industries: Ask, "Is

this failure mode associated with a critical characteristic?" (Critical

characteristics are measurements or indicators that reflect safety or

compliance with government regulations and need special controls.) If so, a

column labeled "Classification" receives a Y or N to show whether

special controls are needed. Usually, critical characteristics have a severity

of 9 or 10 and occurrence and detection ratings above 3.

13. Calculate

the risk priority number, or RPN, which equals S × O × D. Also calculate

Criticality by multiplying severity by occurrence, S × O. These numbers provide

guidance for ranking potential failures in the order they should be addressed.

14. Identify

recommended actions. These actions may be design or process changes to lower

severity or occurrence. They may be additional controls to improve detection.

Also note who is responsible for the actions and target completion dates.

15. As

actions are completed, note results and the date on the FMEA form. Also, note

new S, O, or D ratings and new RPNs.

FMEA

EXAMPLE

A bank performed a process FMEA on their ATM system. Figure 1

shows part of it: the function "dispense cash" and a few of the

failure modes for that function. The optional "Classification" column

was not used. Only the headings are shown for the rightmost (action) columns.

Notice that RPN and criticality prioritize causes differently.

According to the RPN, "machine jams" and "heavy computer network

traffic" are the first and second highest risks.

One high value for severity or occurrence times a detection

rating of 10 generates a high RPN. Criticality does not include the detection

rating, so it rates highest the only cause with medium to high values for both severity

and occurrence: "out of cash." The team should use their experience

and judgment to determine appropriate priorities for action.

Comments

Post a Comment